WHAT DO WE DO?

We offer SENSORIZATION SYSTEMS that allow the acquisition of parameters with two objectives::

• Increase efficiency and profitability of maintenance tasks

• Increase the quality of production by adding sensorization characteristics

Regarding systems for maintenance, we distinguish two types, first being industrial sensorization implementing a predictive maintenance model, avoiding production stops and deviation in the production line . The second type deals with telematic control of installations using actuators to intervene in the processes and sensors to monitor them. To support implementation, we have our own team of electronic engineers that will take good care of your new sensorization product..

NEW PRODUCT

We offer our knowledge and expertise gathered through years of experience with development of PCBs and sensorization devices for the modification of existing products or creation of new products using sounding line to obtain information and communication with servers. We are capable of both working with low power energy and working on products in real-time.

PHASES OF THE PROJECT

- The first phase of any project is thorough study of the product, a meeting of features and specifications that will define the firmware functionalities and the hardware components that your product will have.

- After the necessary iterations for the first phase and outlining a clear definition of the product we begin the second phase specific to the electronic design. In this part we select the components that best fit, proceed to the creation of the schematics and finally to the layout resulting in a detailed model.

- If the second phase is approved by the client, we proceed to the realization of prototyping units to validate the design.

- And finally, once the product design has been validated, we manage the mass production of as many units as needed..

We have worked in the following sectors: Private security (sending alerts, control of resources), Domotics (Lighting), HealthCare (alerts for epilepsy attacks, heart), Transportation (Tracking of commercial vehicles), Research (Monitoring brain impulses)

PREDICTIVE MAINTENANCE

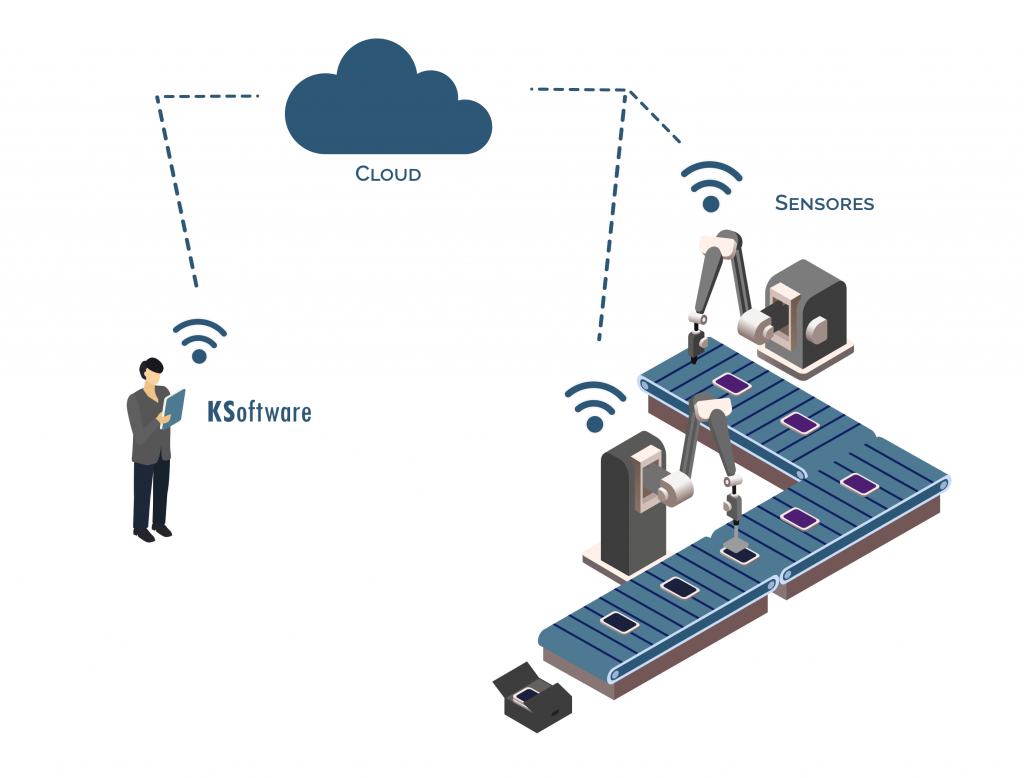

Our system consists of:

- an acquisition device to which the industrial sensors specific to the environment at hand are connected

- software where all of the information is stored and through which machine learning obtains a series of predictions regarding the asset

The acquisition device has been developed by our team of electronic engineers and has inputs for both analog and digital sensors, it is also able to obtain information on the different infrastructures already existing in the plant (profibus, profinet, plcs …).

HOW DOES IT WORK?

- Our predictive maintenance system uses the relevant sensors to carry out data collection.

- All the information is sent through data communication protocols agreed with the client and ALWAYS accompanied by the best security are sent to the cloud (AWS, Azure, the client’s own server, our servers).

- Finally, the client has a platform for the visualization of the data (KSoftware, a software that the client already has, visualization system of the cloud itself).

Using our software, created ad hoc according to the needs of each company and installed in electronic devices, it is possible to make the most appropriate decisions to achieve optimization of processes and resources.

TELEMATIC MAINTENANCE

Today there is an immense amount of facilities that require provision of human resources, our mission is to centralize and execute all these operations of maintenance and monitoring remotely. For this, we can install our sensorization system with actuators which are capable of executing the aforementioned operations through electric, pneumatic and hydraulic actuators. This means it is possible to modify the speed of an engine, control the on and off of diffusers and purge heating systems, all remotely.

SYSTEM INSTALLATION PHASES

- First phase of study where we will propose a system of sensors and actuators that cover the needs of the installation.

- The second step will be the laboratory testing and tests with the new installation, facilitating a portal to the client where they can follow the whole process and check the results of the installation.

- Once the entire system works as stipulated in the description and goes through the analysis phase, the system control panel is configured where the customer can comfortably and easily enjoy all the utilities of the telematic maintenance service.

ADVANTAGES OFFERED BY TELEMATIC MAINTENANCE

- Increased efficiency, real-time management

- Increase in the quality of the service, monitoring the installation

- Decreased funds spent on human resources and transportation

WHY CHOOSE OUR SENSOR SYSTEM

The system is independent of any machine and can be installed without special requirements.

The sensor configuration and the hub application can be updated at any time. Applications can be adapted and expanded, as needed.

Reduction of long-term costs through utilizing internationally standardized connections and interfaces.